2019年1月1日 The requisite coke quality has been a problem for the iron and steel industry in general according to the BF requirement. It is well known that the three factors which control coke strength are (1) selection of coals for coal blend, (2) adopted cokemaking

2019年1月1日 The resources of hard coking coals of good quality are limited, therefore the development of a cokemaking technology based on the utilization of semisoft coking

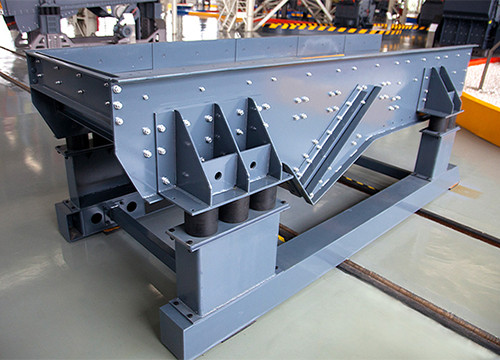

2021年8月3日 In the present work, experiments are conducted on the preparation of coking batch using an improved system based on a preliminary vibrational compactor and

2019年1月1日 Methods of coal compacting in cokemaking 297 11.4 Analysis of the coal compacting process 300 11.4.1 Compacting by stamping 300 11.4.1.1 Experimental

2021年12月8日 Coke chemical companies often have a deficit of coals of particularly valuable grades, the coking coals. This work studies the opportunity of producing

1989年1月1日 It is generally manufactured in by-product recovery ovens for use in the iron blast furnace, cupola and various metal smelters.

2021年3月19日 Coke Oven Equipment Coke Oven Coking Process Brief: The coke pusher car takes raw coal from the coal tower, stamps and presses them to coal cakes, then pushes the coal cakes into the coking

2015年3月21日 The yield of coking by-products is one of the key ways to achieve these goals. This review article is focused on history of the by-products such as coal tar, coal

2021年4月6日 In the cupola the only function of the coke is to furnish heat to melt the iron, whereas in the blast-furnace the function is twofold to supply carbon monoxide for

2019年9月16日 It is a porous, carbon-rich solid fuel made by "coking" coal in large “slot ovens” to drive out most of the volatile materials to the atmosphere.

2019年1月1日 This chapter explains the technological principles behind semisoft coking coal utilization from the viewpoint of the mechanism of carbonization and reviews the development and commercialization of technologies, such as briquette blending carbonization process, coal moisture control, dry-cleaned and agglomerated

2021年12月8日 The thermogravimetric and differential thermal analyses (TGA–DTA) were conducted using an SDT Q600 thermal analyzer. The mass of the petroleum coke additive sample was taken within the range of 8.158–12.641 mg. The heating was conducted from 50 to 900 °C at 20 °C/min. The oxidizing atmosphere used was air.

1. Introduction At present, economic and reasonable coal blending is very important in coking production in China. Coking coal enterprises need a series of coal matching tests such as...

The function of the coking unit function is to upgrade the heavy feedstock (s) into more valuable liquid products, and heavy sour crudes have significantly higher amounts of vacuum resid in the feed, the coking unit (especially the delayed coker) is typically one of the most overwhelmed in terms of capacity.

2015年3月21日 Existing energy resources are struggling to cope with the current energy requirements. It is therefore, necessary to increase energy efficiency and reduce greenhouse gases emissions in integrated steel industries. The yield of coking by-products is one of the key ways to achieve these goals. This review article is focused on history of

2021年3月19日 Coke Oven Equipment Coke Oven Coking Process Brief: The coke pusher car takes raw coal from the coal tower, stamps and presses them to coal cakes, then pushes the coal cakes into the coking

2013年9月3日 As is widely known, this process makes possible to obtain a coal cake with high density (up to 1080 kg/dm 3,dry base), as long as an optimum moisture content is present in the blend (around...

2018年11月7日 Through optimizing the structure of coal blending system, the accuracy and stability of coal blending process control system can be improved, the coal blending error can be reduced, and the...

2021年4月6日 In the cupola the only function of the coke is to furnish heat to melt the iron, whereas in the blast-furnace the function is twofold to supply carbon monoxide for reducing ore and heat to melt the iron. In the cupola it is desired to produce a minimum of carbon monoxide because the heat required to form this gas is net available for melting.

Contribute to dinglei2022/en development by creating an account on GitHub.

2019年1月1日 This chapter explains the technological principles behind semisoft coking coal utilization from the viewpoint of the mechanism of carbonization and reviews the development and commercialization of technologies, such as briquette blending carbonization process, coal moisture control, dry-cleaned and agglomerated

2021年12月8日 The thermogravimetric and differential thermal analyses (TGA–DTA) were conducted using an SDT Q600 thermal analyzer. The mass of the petroleum coke additive sample was taken within the range of 8.158–12.641 mg. The heating was conducted from 50 to 900 °C at 20 °C/min. The oxidizing atmosphere used was air.

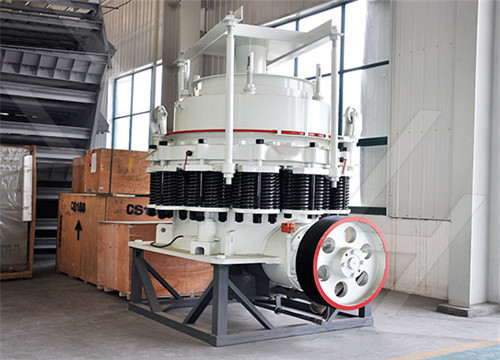

2017年1月16日 Coke-making equipment from coals has developed from the beehive oven to the jumbo coking reactor. Modern coke ovens are mainly composed of carbonization chambers, combustion chambers, regenerators, and coke-oven machinery. The prepared coal is charged into carbonization chambers by a larry car.

1. Introduction At present, economic and reasonable coal blending is very important in coking production in China. Coking coal enterprises need a series of coal matching tests such as...

2015年3月21日 15 Citations 7 Altmetric Metrics Abstract Existing energy resources are struggling to cope with the current energy requirements. It is therefore, necessary to increase energy efficiency and reduce greenhouse gases emissions in integrated steel industries. The yield of coking by-products is one of the key ways to achieve these goals.

2020年8月1日 Just over 1000 Mt of coking coal was produced in 2018, accounting for 14 % of world coal production. Generally, coking coal costs more than steam coal and its m arket is limited to the steel industry.

Coking coal, or metallurgical coal, has been produced in the United States for nearly 200 years. Coking coal is primarily used in the production of coke for use in the steel industry, and for other uses (for example, foundries, blacksmithing, heating buildings, and brewing). Currently, U.S. coking coal is produced in Alabama, Arkansas, Pennsylvania, Virginia,

2021年4月6日 In the cupola the only function of the coke is to furnish heat to melt the iron, whereas in the blast-furnace the function is twofold to supply carbon monoxide for reducing ore and heat to melt the iron. In the cupola it is desired to produce a minimum of carbon monoxide because the heat required to form this gas is net available for melting.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين