2011年4月1日 The critical area of concern in any chrome ore beneficiation plant is the grinding circuit followed by beneficiation circuit comprising gravity units such as wet shaking tables and spirals. The effectiveness of grinding circuit depends on the consistent feed

2023年1月1日 The purpose of beneficiation is to concentrate the ore mineral physically and chemically suitable for subsequent applications. The gravity concentration is a well-established and widely accepted technique for chrome ore beneficiation due to the density difference between the chromite mineral and other associated gangue-bearing minerals.

2011年4月1日 The purpose of beneficiation is to render the ore concentrate physically (granulometry) and chemically suitable for subsequent treatments. Beneficiation practices depend on the mineral characteristics of the ore deposits, gangue mineral assemblage and the degree of dissemination of constituent minerals.

2017年8月28日 tailings from a chrome ore beneficiation plant in the Sukinda region, Odisha; methods used for the study of the beneficiated tailings are QEMSCAN®, X-ray diffraction (XRD), and mineral chemistry by a scanning electron microscope equipped with an energy-dispersive spec-

2016年10月19日 The most commonly used beneficiation methods for chromite ores a re gravity separation such as shaking table but in some cases chromite ore also occur with magnetite.

Chromium Ore. Knowledge of the chromium ore minerals proper and their associated rocks-forming minerals is needed to explore new chromite fields and to predict the efficiency of individual methods for the beneficiation of chromite

2014年8月20日 Chromite tailings are generated from chrome ore beneficiation plants, containing substantial quantities of ultrafine particles. Generally these ultrafine particles of chromite cannot be treated effectively using conventional beneficiation methods, because of limitations in particles size being treated by these processes.

Chrome ore beneficiation. Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: > Communition (for preparing the material for the subsequent unit operations) > Concentration (classification and beneficiation).

2016年11月4日 alternative methods to improve classical methods using for chromite enrichment commonly based on gravity separation such as shaking table, jig, spiral and Reichert cone (Agacayak et. al, 2004

2020年7月14日 The beneficiation studies of low-grade chromite ore from Ghutrigaon reveals that it can be upgraded through physical beneficiation methods. Following gravity concentration technique, a feed of 16% Cr 2 O 3 can be upgraded to 40.1%, with 23% yield, 58% recovery and Cr/Fe ratio of 3.35.

2011年4月1日 1. Introduction Chromium is one of the modern industry’s essential element and important raw material for the production of special steel and ferrochrome alloys. Around 90% of mined chromite ore is converted into different grades of ferrochrome by the metallurgical industry.

2023年1月1日 The chrome ore beneficiation circuit, Sukinda is shown in Fig. 3.3. The plant is designed to produce concentrate of three different size ranges, that is, coarse (−1 mm + 106 µm), fine (−106 µm + 70 µm), and ultrafine (−70 µm + 25 µm). The beneficiation circuit comprises of a combination of hydrocyclone, floatex density separator

Knowledge of the chromium ore minerals proper and their associated rocks-forming minerals is needed to explore new chromite fields and to predict the efficiency of individual methods for the beneficiation of chromite ores.

In India, at both the Sukinda and Boula-Nausahi sectors, chrome ore is mined by opencast mechanized mining methods, though a few underground mines exist which are confined to Byrapur in Karnataka and the Boula and Kathpal mines in Odisha. The overall beneficiation scenario is outlined in Figure 4. Performance of gravity concentrators

2018年12月28日 Developing an optimum beneficiation route for a low-grade chromite ore Authors: İlkay Bengü Can Büşra Özsoy Hacettepe University Levent Ergun It-Robotics Abstract and Figures In this study, an...

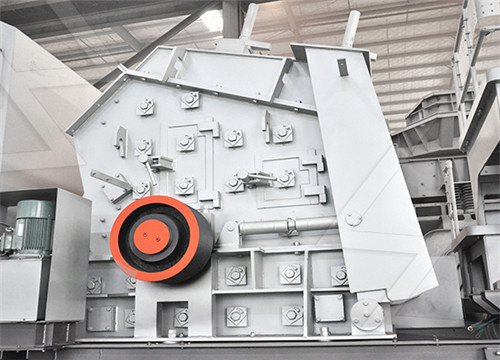

2021年2月24日 Chrome Ore Beneficiation Solution and Equipment As an important kind of ore, chrome ore demonstrates usually a fine-grained style, with a considerable amount of phosphate ore, iron ore, or...

2021年5月27日 Chrome is an important element of stainless steel and an indispensable raw material for industrial production. Chrome ore beneficiation technology is closely related to the physical and chemical properties of chromium ore. This article will introduce you the types of chrome ore, its resource distribution, beneficiation process and equipments, and

Beneficiation includes crushing, grinding, gravity concentration and flotation concentration. Beneficiation is followed by processing activities such as smelting and refining. The beneficiation process begins with milling, which is followed by

2014年7月1日 In conventional chromite beneficiation plant, huge quantity of chromite is used to loss in the form of tailing. For recovery these chromite particles, a gravity concentrator viz. wet shaking table was used and found that, the grade (%) of the concentrate fraction can be achieved to a maximum of 60.8% Cr 2 O 3. Optimisation

2020年10月19日 1. Gravity Separation From the point of production practice, the gravity separation is still the main chrome extraction method in the world method now, which uses the loose stratification in...

2011年4月1日 1. Introduction Chromium is one of the modern industry’s essential element and important raw material for the production of special steel and ferrochrome alloys. Around 90% of mined chromite ore is converted into different grades of ferrochrome by the metallurgical industry.

2023年1月1日 The chrome ore beneficiation circuit, Sukinda is shown in Fig. 3.3. The plant is designed to produce concentrate of three different size ranges, that is, coarse (−1 mm + 106 µm), fine (−106 µm + 70 µm), and ultrafine (−70 µm + 25 µm). The beneficiation circuit comprises of a combination of hydrocyclone, floatex density separator

Knowledge of the chromium ore minerals proper and their associated rocks-forming minerals is needed to explore new chromite fields and to predict the efficiency of individual methods for the beneficiation of chromite ores.

2023年5月13日 The predominant method to concentrate chromite stone is gravity separation. However, given the slightly different chromite properties around the world, magnetic separation, flotation, chemical beneficiation, and combined beneficiation methods can also be used flexibly. Chrome ore gravity separation

Most of the chrome ores around the world are beneficiated by gravity concentration techniques. A conventional chromite ore beneficiation process plant ( Figure 3) consist of two sections:

2021年5月27日 Chrome is an important element of stainless steel and an indispensable raw material for industrial production. Chrome ore beneficiation technology is closely related to the physical and chemical properties of chromium ore. This article will introduce you the types of chrome ore, its resource distribution, beneficiation process and equipments, and

2014年7月1日 In conventional chromite beneficiation plant, huge quantity of chromite is used to loss in the form of tailing. For recovery these valuable mineral, a gravity concentrator viz. wet shaking table was used. Optimisation along with performance prediction of the unit operation is necessary for efficient recovery.

to a water-soluble state and further gravitation beneficiation on concentration tables to obtain a fine-grained rich chromium concentrate. Silica, calcium, and iron oxide additives are used to produce pellets from the fine chrome concentrate, serving as binding agents and enabling the production of hard chrome pellets during roasting. In the

beneficiation methods and routes (Bergmann et al., 2016; Tripathy et al., 2013). Even if the mineral to be enriched is the same, to beneficiate the ores obtained from different regions, the corresponding distinctive process flowsheets should be studied. In other words, the design of the beneficiation routes should be ore based.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين