2 之 Our three-roll mills offer the reliability, high raw material yield and gentle dispersion of contamination, as well as the temperature-sensitive products you need for

2 之 Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions to match the

2022年1月26日 diagram of VRM. 2.3. Grinding Performance Indexes In the field of mineral processing, the specific energy Ecs (kWh/kg) is often used to compare the

2015年11月19日 Introduction to Rolling Process CHAPTER 1 1.1 Definition of Rolling Process Rolling is the most important metal forming process. More than 95% of ferrous

For saving energy and achieving good quality products, we have developed a THREE ROLLER MILL and a CLASSIFIER for it which ensures consistent output upto 500 Mesh.

2022年7月21日 2022-07-21 15:17:25 Three-roll mill for short, three-roll mill can be divided into two types: experimental three-roll mill and production three-roll mill. The three-roll

However, the 3 roll mill is capable of a lot more, with its shear force developed through the three horizontally placed rolls rotating in opposite directions and varying speeds. The following discussion helps you

Download scientific diagram The 3D geometry model of the vertical roller mill. 1: separator outlet; 2: separator; 3: shell; 4: return hopper; 5: grinding roller; 6: wind ring; 7: air inlet; 8

2019年5月20日 The mill design starts with the flow diagram (grinding diagram). The preparation of the mill diagram is the selection and design of order, types, number, and specification of grinding units by taking into

Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a two-chamber ball mill and the separator (Plasari and T heraska, 19 81). Cement clinker is usually

2 之 roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions. Diagram 186: Download June 23 issue. People. People. Careers; Working at ; Lifelong learning; TOP Values; Diversity, equityinclusion; Direct Career Start; Apprenticeship

2016年1月20日 Sankey diagram of raw roller mill system. 4.2. The primary part materials (133.93 t/h) flow into the cement mill for grinding, and then elevated to the vortex classifier. The materials from the cement mill and the cyclone dust collector are classified according to their size. The coarse material (63.23 t/h), accounting for 26.97% of the

Grinding unit with vertical plate, 1 -grinding roller, 2 -sloped plate, 3 -milled material, 4 -plate deflection mechanism, -the angle between the roller and the plate, χ -the gap between...

2016年1月1日 Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm. The spring pressure for light duty rolls varies between 1.1 and 5.6 kg/m. The heavy duty crusher diameters range between 900 and 1000 mm with face

Context 1 of the Pfeiffer's 2800 C vertical roller grinding mill with high -efficiency guide -vane bladed -rotor classifier (slat) is shown in Fig. 1. The feed (f) is led into the...

2012年6月1日 Abstract and Figures. The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy

Three Roll Mills. EXAKT three roll mills are used in a wide variety of industrial and research applications. They can break open all kinds of agglomerates creating fineness and quality in each dispersion. Customize your mill by choosing between five models, various roller diameters, roller lengths, and roller materials.

2022年5月24日 Following are the 6 different types of rolling mills used in many industries: Two high rolling mills. Three high rolling mills. Four high rolling mills. Cluster rolling mills. Planetary rolling mills. Tendem or

Process Control A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 18.9.3 Grinding Mill Control in Closed Circuit The principle objective for controlling grinding mill operation is to produce a product having an acceptable and constant size distribution at

2019年5月20日 “The mill design starts with the flow diagram (grinding diagram). The preparation of the mill diagram is the selection and design of order, types, number, and specification of grinding units by taking into

Context 1 of the Pfeiffer's 2800 C vertical roller grinding mill with high -efficiency guide -vane bladed -rotor classifier (slat) is shown in Fig. 1. The feed (f) is led into the...

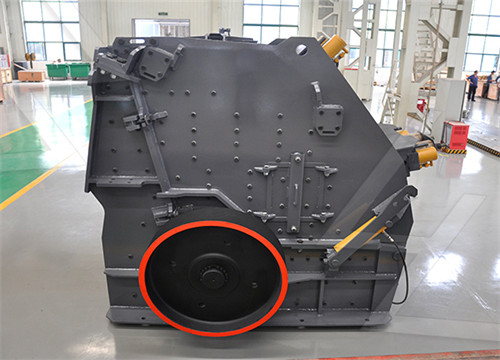

2016年1月1日 6.1. Introduction Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the rolls are nipped and then crushed as they pass between the rolls.

Three Roll Mills EXAKT three roll mills are used in a wide variety of industrial and research applications. They can break open all kinds of agglomerates creating fineness and quality in each dispersion. Customize your mill by choosing between five models, various roller diameters, roller lengths, and roller materials. G-Series

Process Control A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 18.9.3 Grinding Mill Control in Closed Circuit The principle objective for controlling grinding mill operation is to produce a product having an acceptable and constant size distribution at

2012年6月1日 Abstract and Figures. The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy

2022年5月24日 Following are the 6 different types of rolling mills used in many industries: Two high rolling mills. Three high rolling mills. Four high rolling mills. Cluster rolling mills. Planetary rolling mills. Tendem or

The roller mill is an air swept vertical ring-roll with an integral classification system. A vertical shaft rotates a “spider” assembly of arms from which are suspended free swinging journal assemblies with rolls attached. As the unit turns, centrifugal force drives the rolls against the inner surface of the vertical grinding ring.

2021年4月12日 The grinding parts on grinding rollers and grinding track are replaceable segments which are made of wear-resistant material. 3.2 Structure of a MLS mill You can see from fig. 1 that the major

2023年5月30日 3 roller Plate Rolling Machine Working Principle Animation. The process of rolling steel plate involves placing the plate between upper and lower rollers. The three cutting points exposed to the metal sheet by

Pada proses produksi semen, posisi Raw Grinding Mill diberikan pada diagram dibawah ini, dimana pengeringan dan penggilingan merupakan tahap kedua dari tahapan proses produksi secara umum Material yang digiling dengan mesin Raw Grinding Mill ini yaitu limestone, clay, silika sand dan iron sand.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين