2022年1月1日High-energy ball milling and spark plasma sintering of molybdenum lanthanum oxide (Mo-La2O3) and molybdenum lanthanum zirconate (Mo-La2Zr2O7)

zirconia balls have following advantages in solid state synthesis in ball milling. High crushing strength and fracture durability, superior wear resistance which has no any

2014年8月1日It has been demonstrated that milling of the mixture in an AGO-2 planetary mill for 2–10 min considerably enhances the rate of calcium zirconate synthesis in the

2001年6月1日Lead zirconate (PbZrO 3 or PZ) powder was successfully synthesized by a high-energy ball milling process using oxides as starting materials. The milled powders

Kong, L.B., Ma, J., Zhu, W. et al. Phase formation lead zirconate titanate via a high-energy ball milling process. Journal of Materials Science Letters 21, 25–27 (2002).

2013年3月1日The properties of zirconia powder prepared by alcohol-aqueous method after ball-milling had been researched by BET,XRD,TEM and laser granularity instrument.The results show that by using...

2007年1月1日This contribution explored the effects of ball milling time on properties of a lead zirconate titanate (PZT) aqueous suspension. The particle size distribution, stability and rheological...

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the

This contribution explored the effects of ball milling time on properties of a lead zirconate titanate (PZT) aqueous suspension.The particle size distribution, stability and rheological...

2022年1月1日High-energy ball milling and spark plasma sintering of molybdenum lanthanum oxide (Mo-La2O3) and molybdenum lanthanum zirconate (Mo-La2Zr2O7) composite powders ScienceDirect International Journal of Refractory Metals and Hard Materials Volume 102, January 2022, 105717

2022年9月2日In this work, calcium barium zirconate titanate piezoelectric ceramics 0.4Ba(Zr0.2Ti0.8)O3- 0.6(Ba0.7Ca0.3)TiO3((1−x)BZT-xBCT, abbreviated as x BCZT, x = 0.6) were prepared by conventional solid state reaction method. Different surfactant additives (SDS, CTAB, PEG, and Tris–HCl, respectively) were added to the ball milling

2001年6月1日Lead zirconate (PbZrO 3 or PZ) powder was successfully synthesized by a high-energy ball milling process using oxides as starting materials. The milled powders were characterized by XRD, SEM and particle size analysis. Perovskite PZ phase is predominant in the milled powder with an average particle size of about 20 nm.

2014年8月1日High-energy ball milling of the (ZrO 2 +CaCO 3) mixture results in decrease in the temperature of CaZrO 3 formation during annealing at 950 °C.

At present, the synthesis methods of MOFs mainly include the hydrothermal method, microwave assisted method, ultrasonic assisted method, electrochemical method, and ball milling (BM) method [12,13,14,15].Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials.

2022年1月1日High-energy ball milling and spark plasma sintering of molybdenum lanthanum oxide (Mo-La2O3) and molybdenum lanthanum zirconate (Mo-La2Zr2O7) composite powders ScienceDirect Abstract Introduction Section snip International Journal of Refractory Metals and Hard Materials Volume 102, January 2022, 105717

2017年4月7日The lack of the rapid and direct synthesis of a perovskite product by a planetary ball mill is attributed to a kinetic limitation associated with difficulties in developing a mill capable of...

Lithium lanthanum zirconate (LLZO) is a promising Li + ion conductor for applications as a ceramic solid electrolyte in all-solid-state lithium batteries. Low-temperature synthesis of cubic phase Li7La3Zr2O12 via sol-gel and ball milling induced phase transition. Journal of Power Sources 2019, 412,189-196.

Phase formation lead zirconate titanate via a high-energy ball milling process. L. B. Kong 1, J. Ma 1, W. Zhu 2 O. K. Tan 2 Show authors. Journal of Materials Science Letters volume 21, pages 25–27 (2002)Cite this article

Nevedomskii, V. N. ; Kalinkina, E. V. ; Balyakin, K. V. Monophase calcium zirconate (CaZrO 3) has been prepared from the equimolar ZrO 2 + CaCO 3 mixture by two-step synthesis process. In the first step, mechanical treatment of the mixture is performed in an AGO-2 planetary ball mill.

2022年9月2日In this work, calcium barium zirconate titanate piezoelectric ceramics 0.4Ba(Zr0.2Ti0.8)O3- 0.6(Ba0.7Ca0.3)TiO3((1−x)BZT-xBCT, abbreviated as x BCZT, x = 0.6) were prepared by conventional solid state reaction method. Different surfactant additives (SDS, CTAB, PEG, and Tris–HCl, respectively) were added to the ball milling

Lithium lanthanum zirconate (LLZO) is a promising Li + ion conductor for applications as a ceramic solid electrolyte in all-solid-state lithium batteries. Low-temperature synthesis of cubic phase Li7La3Zr2O12 via sol-gel and ball milling induced phase transition. Journal of Power Sources 2019, 412,189-196.

Phase formation lead zirconate titanate via a high-energy ball milling process. L. B. Kong 1, J. Ma 1, W. Zhu 2 O. K. Tan 2 Show authors. Journal of Materials Science Letters volume 21, pages 25–27 (2002)Cite this article

At present, the synthesis methods of MOFs mainly include the hydrothermal method, microwave assisted method, ultrasonic assisted method, electrochemical method, and ball milling (BM) method [12,13,14,15].Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials.

2022年1月1日High-energy ball milling and spark plasma sintering of molybdenum lanthanum oxide (Mo-La2O3) and molybdenum lanthanum zirconate (Mo-La2Zr2O7) composite powders ScienceDirect Abstract Introduction Section snip International Journal of Refractory Metals and Hard Materials Volume 102, January 2022, 105717

DOI: 10.1016/j.ijrmhm.2021.105717 Corpus ID: ; High-energy ball milling and spark plasma sintering of molybdenum lanthanum oxide (Mo-La2O3) and molybdenum lanthanum zirconate (Mo-La2Zr2O7) composite powders

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the mostinteresting applications of this technology in thefield of cellulose is the preparation and the chemicalmodification of cellulose nanocrystals and nanofibers.

161 Accesses 16 Citations Metrics Abstract Lead zirconate titanate stannate powders doped with lanthanum and niobium, namely [Pb 0.99 Nb 0.02 (Zr 0.85 Sn 0.13 Ti 0.02) 0.98 O 3, or PNZST) and (Pb 0.9 La 0.02 (Zr 0.65 Sn 0.31 Ti 0.04 )O 3, or PLZST], were synthesized by a high-energy ball milling technique from their corresponding oxide

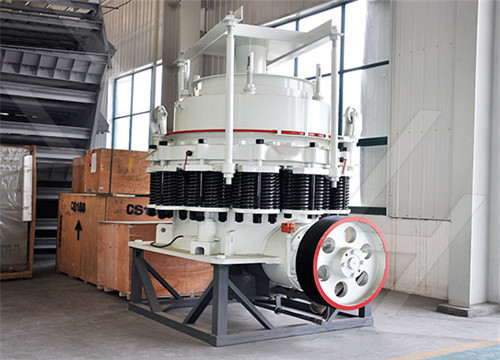

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين