2016年6月10日Until now, flotation has not been successful to recover nickel from laterite ores. • Fine grinding should be used to liberate nickel-containing particles in laterite ores.

2018年7月26日The Critical Role of Pulp Density on Flotation Separation of Nickel-Copper Sulfide from Fine Serpentine by Yawen Gao 1, Guofan Zhang 1,2,*, Mengtao

2022年7月13日ABSTRACT. The following review is Part III of a series concerned with the direct hydrometallurgical processing of nickel sulfide flotation concentrates. In the first

2022年5月16日The extraction of nickel (Ni) from sulfide resources commences with flotation to produce a concentrate which is then smelted to produce a nickel-enriched

A clean and satisfactory separation ofpentlandite from pyrrhotite by Sotation is difRcultin practice since pyrrhotite typically contains inter-grown inclusions of pentlandite as well as

Nickel can be completely separated from a hundredfold excess of cobalt by complexing the latter with nitroso-R-salt before flotation. Iron does not float on its own but recoveries of

Nickel can be completely separated from a hundredfold excess of cobalt by complexing the latter with nitroso-R-salt before flotation. Iron does not float on its own but recoveries of

2021年6月1日Abstract. This study investigates the most suitable conditions for the combined separation of nickel and zinc ions from aqueous solution using

1995年6月1日The selective flotation of pentlandite from a nickel ore. Nickel sulphide ores containing pentlandite, pyrrhotite and talc have traditionally been treated by bulk

2022年5月16日Nickel concentrate from both operations is combined and processed in a beneficiation circuit where feed is re-ground to a P 80 of 30–40 µm followed by magnetic separation to reject pyrrhotite, and flotation to remove talc and magnesite, to produce an upgraded concentrate containing 12.4% Ni (Laukka et al. Citation 2018; Neale et al.

2022年7月13日Discussion of research carried out to date on the bioleaching of nickel flotation concentrates is limited to studies after 2008, and readers are referred to the review by Watling The pentlandite used in the study was a high-quality sample prepared by flotation and magnetic separation that graded 27.43% Ni.

2018年7月26日The Critical Role of Pulp Density on Flotation Separation of Nickel-Copper Sulfide from Fine Serpentine by Yawen Gao 1, Guofan Zhang 1,2,*, Mengtao Wang 1 and Dezhi Liu 1 1 Department of Mineral Engineering, School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China 2

2016年6月10日In fact, no physical separation technique (including flotation) has been able to dramatically upgrade nickel in laterite ores (Quast et al., 2015a). The only isolated case with an acceptable nickel upgrading is the result by Denysschen and Wagner (2009).

Recently, several researchers have focused on the reduction roasting of laterite ore with different reductants such as carbon, CO or H 2, followed by magnetic separation ( Lu et al., 2013; Quast et al., 2015b ).

2023年4月19日In the flotation separation of pentlandite and fine quartz, CMC can be used to inhibit quartz recovery with a marginal impact on pentlandite recovery. Discover the world's research 25+ million members

2022年7月13日However, for a high nickel-sulphur flotation system, it is still an open question as to how many sample types there are throughout its production process. The best clustering analysis was performed for each of the five subsystems as well as concentrate system, swept separation system,

1995年6月1日An investigation into the flotabilities of pentlandite and pyrrhotite in this laboratory, using mixtures of these minerals with quartz (Senior et al., 1994), has confirmed that a reasonably selective separation is possible provided three conditions are met: first, that copper sulphate not be added; second, that the pulp pH be set to a sufficient...

2002年5月1日Flotation of Cesium Coprecipitated with Nickel Hexacyanoferrate(II) from Aqueous Solutions and Radioactive Waste Simulants. Separation Science and Technology 2007,42 (6),1341-1365.

2020年5月1日In the flotation process of serpentine-containing copper-nickel sulfide ore, serpentine slime coatings significantly reduced the flotation performance of copper-nickel sulfide. Sodium phytate is a highly effective dispersant for MgO control in the flotation of copper-nickel ore.

2022年5月16日The extraction of nickel (Ni) from sulfide resources commences with flotation to produce a concentrate which is then smelted to produce a nickel-enriched phase called matte, and further refined to produce pure Ni products as well as by-products, such as cobalt (Co), copper (Cu) and precious metals.

2022年7月13日Discussion of research carried out to date on the bioleaching of nickel flotation concentrates is limited to studies after 2008, and readers are referred to the review by Watling The pentlandite used in the study was a high-quality sample prepared by flotation and magnetic separation that graded 27.43% Ni.

2016年6月10日In fact, no physical separation technique (including flotation) has been able to dramatically upgrade nickel in laterite ores (Quast et al., 2015a). The only isolated case with an acceptable nickel upgrading is the result by Denysschen and Wagner (2009).

2022年7月11日The Direct Leaching of Nickel Sulfide Flotation Concentrates A Historic and State-of-the-Art Review Part II: Laboratory Investigations into Pressure Leaching Nebeal Faris,Mark I. Pownceby,Warren J. BruckardMiao Chen Published online: 11 Jul 2022 Download citation https://doi/10.1080/.2022. In this article Full Article

Recently, several researchers have focused on the reduction roasting of laterite ore with different reductants such as carbon, CO or H 2, followed by magnetic separation ( Lu et al., 2013; Quast et al., 2015b ).

2023年2月24日Improving Nickel Recovery in Froth Flotation by Purifying Concentrators Process Water Using Dissolved Air Flotation by Annukka Aaltonen 1,2,*, Thi Minh Khanh Le 1, Eija Saari 1, Olli Dahl 2, Benjamin Musuku 2,3, Aleksandra Lang 4, Sakari Hiidenheimo 1 and Richard Dixon 5 1 Metso Outotec Finland Oy, Rauhalanpuisto 9, 02230 Espoo,

2021年7月8日Abstract. Removal of heavy metal ions from wastewater is of prime importance for a clean environment and human health. Different reported methods were devoted to heavy metal ions removal from

2023年4月19日In the flotation separation of pentlandite and fine quartz, CMC can be used to inhibit quartz recovery with a marginal impact on pentlandite recovery. Content uploaded by Linda Dzetugbi Ayedzi...

Application of NARX Model in Nickel Flotation System 1167 Table 1. The ore pulp flow relationship. Index Name From To 1 Ore pulp Ore grinding Overflow of swept separation column 1# Underflow of concentrate column 1# Hydrocyclone 2 Particle size selecting ore pulp Hydrocyclone Roughing flotation column 3 Nickel enriching pulp Underflow of

2020年5月1日In the flotation process of serpentine-containing copper-nickel sulfide ore, serpentine slime coatings significantly reduced the flotation performance of copper-nickel sulfide. Sodium phytate is a highly effective dispersant for MgO control in the flotation of copper-nickel ore.

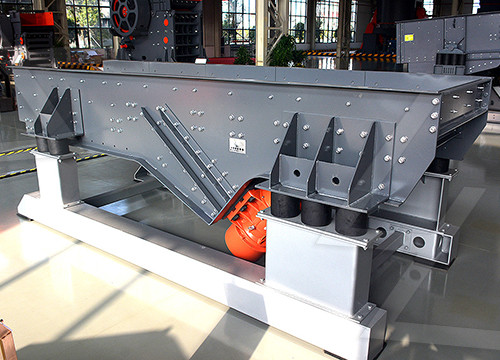

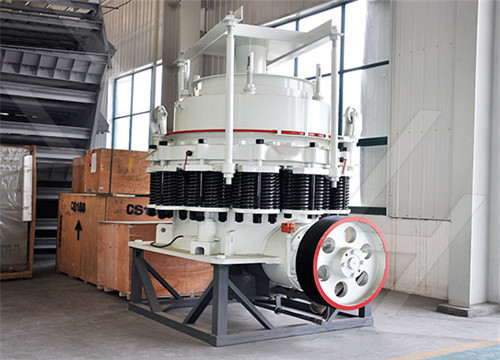

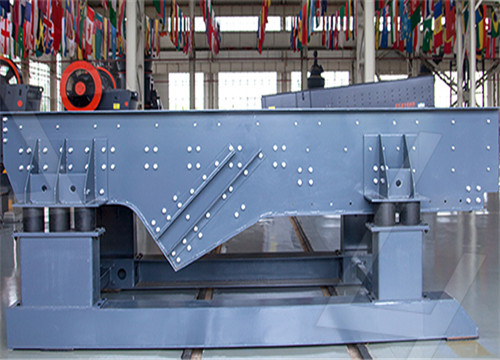

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين