2016年1月1日Abstract. Impurities limit the application of low-grade bentonite, resulting in a large waste of resources. A simple physical method composed of grinding, dispersion and centrifugation was adopted to purify a low-grade bentonite from Zhejiang, China.

2020年5月3日In order to have a uniform PSD for the steel dust and bentonite mixture, the steel dust samples were sieved through 200 mesh (75 µm) to remove course

2016年1月1日The influence of the grinding time of raw bentonite, the dispersant dosage in bentonite dispersion, and the centrifugal speed on the purification of bentonite were

The utility model discloses reduce the bentonite powder in the workshop and discharged, the noise reduction has improved the production environment, the cost is reduced.

the drying and grinding of bentonite and limestone. Cyclones and cyclone batteries are used as the first and second cleaning stages, the gases being finally cleaned before

2021年12月30日PDF In this study, a pin-type vertical stirred media mill was used to perform the dry grinding of bentonite. Grinding time and stirring speed were Find,

2015年6月5日Bentonite powder production line,Bentonite production line,Bentonite powder process line

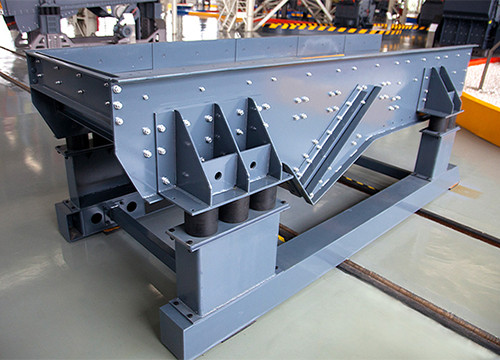

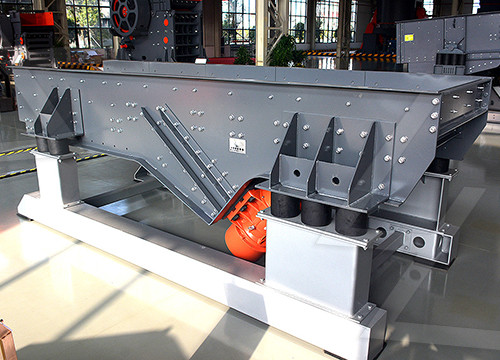

According to the properties of bentonite, the equipment used in the bentonite production line mainly includes jaw crusher, impact crusher, Raymond mill, and some auxiliary

2015年6月5日Bentonite production line. Bentonite production line Introduction of Bentonite production line: Brand: CLIRIK Type: Micro powder grinding mill Models:

2016年1月1日With the development of modern technology, bentonite application has been transformed from traditional casting, pellet, drilling mud, adsorption agents to some high value-added products like nano materials, medicine, carrier materials and

Dust from powder and bulk powder solids production is a common issue seen by manufacturers that handle powders but it can be solved with Matcon IBC systems Powder Dust Problems Solved Safe, efficient

2020年1月12日This stone also illustrates design analysis and the best selection of a dust collection system for various kinds of manufacturing industries who are facing dust emission and unable to control...

Bentonite is used as a binder for proper balling of the filter cake particles in to spherical shaped balls with certain compression strength. The bentonite is stored and ground in a Vertical mill by dry grinding process to desired fineness (−200 mesh, 80%). The powdered bentonite is stored for further mixing process.

2013年1月1日The bentonite beneficiation were carried out in two stages [9]; samples were milled, screened, washed with distilled water and dried at 105 o C for 3 hr to remove moisture and volatile organics

Substance name : Bentonite Powder Product code : CM015 1.2.Relevant identified uses of the substance or mixture and uses advised against 1.2.1.Relevant identified uses Main use category : Industrial use 1.2.2.Uses advised against Restrictions on use : Uses other than as recommended above. 1.3.Details of the supplier of the safety data sheet

Bentonite powder making is generally divided into four types: coarse powder processing (0-3mm), fine powder processing (20 mesh-400 mesh), superfine powder processing (400 mesh-1250 mesh) and micro powder processing (1250 mesh-3250 mesh). Below 200 mesh: used as feed, such as fish feed, etc., and also used as other additives.

2023年5月27日Bentonite clay production process features ore mining, sodium activation (if required), drying, milling, classifying, pelleting, etc. Grinding and drying are key steps. Bentonite mining process

2015年8月11日Barite powder grinding processing method and processing plant Barite Use Barite is a mineral consisting of barium sulfate. Bentonite production line. A small proportion of the fine powders, with airflow, moves to the dust cleaner. The materials from the above two lots are sent by the conveyor to get finished powders packed.

Bentonite is equally useful as a flocculation aid in the treatment of effluent from pulp and stone mills, being effective in the removal from these effluents of starch (Gillespie et al., 1970), ammonium-based spent sulphite liquor (Scherler, 1972), basic dyes (Mobius and Gunther, 1974), and colour and fines generally (Potskhershvili et al., 1977; Ciba-Geigy,

2022年9月29日1. The process of artificial sodiumization of calcium bentonite: Calcium-based soil raw ore → crushing → adding sodium carbonate (wet method also needs to add water) → mixing extrusion → rotary kiln drying → grinding → air classification → sodium-based soil products. 2. The processing flow of active (acidic) clay:

2020年1月12日This stone also illustrates design analysis and the best selection of a dust collection system for various kinds of manufacturing industries who are facing dust emission and unable to control...

2018年6月1日Introduction. Bentonites are clays that consist mainly of montmorillonite (Mt) and are formed from the alteration of volcanic ash and tuff. Mt has drawn great interests due to their useful chemical and physical properties, such as rheological and adsorption properties, cation exchange capacity, plasticity, high bonding strength, and swelling

Substance name : Bentonite Powder Product code : CM015 1.2.Relevant identified uses of the substance or mixture and uses advised against 1.2.1.Relevant identified uses Main use category : Industrial use 1.2.2.Uses advised against Restrictions on use : Uses other than as recommended above. 1.3.Details of the supplier of the safety data sheet

Bentonite powder making is generally divided into four types: coarse powder processing (0-3mm), fine powder processing (20 mesh-400 mesh), superfine powder processing (400 mesh-1250 mesh) and micro powder processing (1250 mesh-3250 mesh). Below 200 mesh: used as feed, such as fish feed, etc., and also used as other additives.

materials such as bentonite by Grassi et al., (2012); Evaluation of the application of bentonite to remove heavy metals from wastewater by Al-Jlil (2010); Evaluation of bentonite soil modification using sulfate and anionic phosphate for the removal of heavy metals by Olu-Owolabi and Unuabonah (2010);

Bentonite is equally useful as a flocculation aid in the treatment of effluent from pulp and stone mills, being effective in the removal from these effluents of starch (Gillespie et al., 1970), ammonium-based spent sulphite liquor (Scherler, 1972), basic dyes (Mobius and Gunther, 1974), and colour and fines generally (Potskhershvili et al., 1977; Ciba-Geigy,

2015年8月11日Barite powder grinding processing method and processing plant Barite Use Barite is a mineral consisting of barium sulfate. Bentonite production line. A small proportion of the fine powders, with airflow, moves to the dust cleaner. The materials from the above two lots are sent by the conveyor to get finished powders packed.

2018年5月26日In order to select the suitable dust removal device, we have to be clear about the features of bentonite powder drying system firstly. The key equipment of bentonite powder drying line is the rotary dryer machine. It is to use high temperature air to heat and dry the wet bentonite continuously and quickly.

As a general-purpose mill, Raymond mill is suitable for bentonite grinding, which can reach the fineness of finished powder in the range of 80-325 mesh. The adjustment range can be changed according to user needs, and it is more It has bright spots such as stable rotation, high screening rate, long life, more energy saving, no pollution, less dust, and the quality

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين