1 The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two

Email: info@ballmillssupplier. is the main equipment for grinding pulverized coal. The raw material of coal powder is coal with various hardness, and it drying in the coal mill

Coal Mill. Coal mill pulverizes coal into a suitable particle size for injecting into a furnace. From: Advances in Power Boilers, 2021. Related terms: Boiler; Power Plant; Grinding

2020年9月1日 Different types of ball milling and its working principles: (a) planetary ball milling, (b) tumbler ball milling, (c) attrition ball milling, and (d) vibration ball milling (where

Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement

Coal Ball Mill Buyers in USA. USA Coal Ball Mill Buyers Directory provides list of USA Coal Ball Mill importers, buyers and purchasers who wanted to import coal ball mill in USA.

2 之 Jar mills are excellent for grinding virtually any type of sample. Analytical and hand mills are ideal for hard and brittle samples. Lab bead mills are used for cell and

2022年9月7日 China Popular Air Swept Coal Ball Mill for South America, Find details about China Ball Mill, Coal Ball Mill from Popular Air Swept Coal Ball Mill for South America

2021年10月19日 America Coal Ore Ball Mill. Ball Mill Girth Gear Specifications Coal Surface Mining The ball mill is a key piece of equipment for grinding crushed materials

1 Description Pulverization of coal is currently the favored method of preparing coal for burning. Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more efficient combustion. Transported by an air or an air/gas mixture, pulverized coal can be introduced directly into the boiler for combustion.

Home CE-Type Pulverizer Parts, Services, and Programs B&W Parts, Services and Programs for CE-Type Pulverizers / Mills B&W applies our vast experience and knowledge of roll wheel and ball-and-race

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills. Our ATOX® coal mill has

2020年9月1日 Ball milling procedure is inexpensive and reproducible. A few studies focused on the use of ball milling to produce novel engineered biochar with enhanced functional characteristics ( Shan et al., 2016, Wang

2007年9月10日 Abstract A Brazilian power plant consumes mineral coal with high ash contents to feed four turbines to generate 450 MW. Four ball mills, 4.2 m in diameter, are fed with crushed coal to deliver the material ground to sizes less than 0.075 μm. High wear rates were observed when using forged high-carbon steel balls.

1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

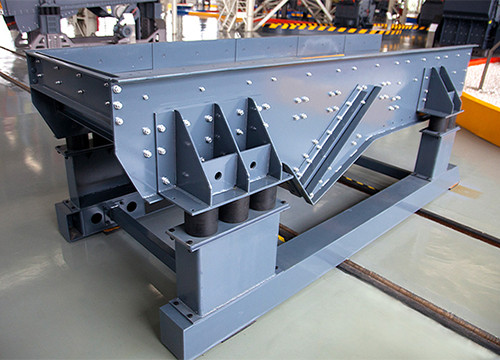

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in open-air environments, greatly reducing the cost of investment. The design of the

AAC Blocks Manufacturing Plant Ball Mill Trunnion Cement Clinker Grinding Plant AAC Blocks Manufacturing Plant Functional advantages: Less failure and reliable operation It is mainly used for grinding coal of various hardnesses, and is also suitable for coal powder making system and ore milling system in cement plants and metal magnesium plants.

[Plate 1] Coal balls (exceptionally preserved calcareous permineralized peat), widely described from tropical Carboniferous Euramerian coal seams, have yielded diverse data on the biology, ontogeny and ecology of swamp plants and ecosystems. Probably over 75 %/ of the swamp taxa may have been preserved, in contrast to probably less then 10 %

2021年7月31日 2.1 Breakage mechanisms in a ball mill 22 2.2 First order reaction model applied to milling 24 2.3 Grinding rate versus particle size for a given ball diameter 25 425 microns coal using 49.2 mm balls 87 A.12 Results of size analysis for + 26500 22400 microns coal for EQM-BSD 88

Home CE-Type Pulverizer Parts, Services, and Programs B&W Parts, Services and Programs for CE-Type Pulverizers / Mills B&W applies our vast experience and knowledge of roll wheel and ball-and-race

2023年5月16日 The global Steel Ball Coal Mill market size is projected to reach multi million by 2030, in comparision to 2021, at unexpected CAGR during 2023-2030 (Ask for Sample Report).

2015年12月10日 Abstract High-energy mill (HEM) has a wide application in material preparation, activation and synthesis. In the present study, fly ash was selected to be milled by HEM under the speed of 700 rpm and the ball-to-powder ratio of 10:1 by weight, but varied periods of milling time.

AAC Blocks Manufacturing Plant Ball Mill Trunnion Cement Clinker Grinding Plant AAC Blocks Manufacturing Plant Functional advantages: Less failure and reliable operation It is mainly used for grinding coal of various hardnesses, and is also suitable for coal powder making system and ore milling system in cement plants and metal magnesium plants.

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in open-air environments, greatly reducing the cost of investment. The design of the

2021年9月17日 1,800,000 tpy Cement Grinding Plant 2800kW Roller Press + 5800kW Ball Mill, 50Hz 420,000 tpy Cement Grinding and Packing Plant, 50Hz 10' X 18' KVS Coal Ball MIlls, Air Swept, 800HP 60Hz (2 units) 3.2m x 4.25m Polysius Air-Swept Coal Mill, 15 tph, 500kW 50Hz. 4.7m X 1.5m Aerofall SAG Mill, Dry Grinding, 550HP 60Hz

2016年1月5日 Ball Mill Liner Design There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial

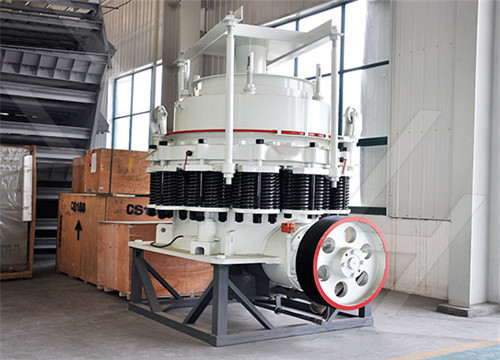

2023年6月16日 Vertical roller mill. We can provide different types of vertical roller mills in different industries such as cement, steel, and mining. The production capacity is 30-250 t/h. More>> Ball mill. As a professional ball mill manufacturer, we can provide different types of ball mills used for grinding cement, coal, slag, etc.

2021年7月31日 2.1 Breakage mechanisms in a ball mill 22 2.2 First order reaction model applied to milling 24 2.3 Grinding rate versus particle size for a given ball diameter 25 425 microns coal using 49.2 mm balls 87 A.12 Results of size analysis for + 26500 22400 microns coal for EQM-BSD 88

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين